Newsroom

02/09/2025

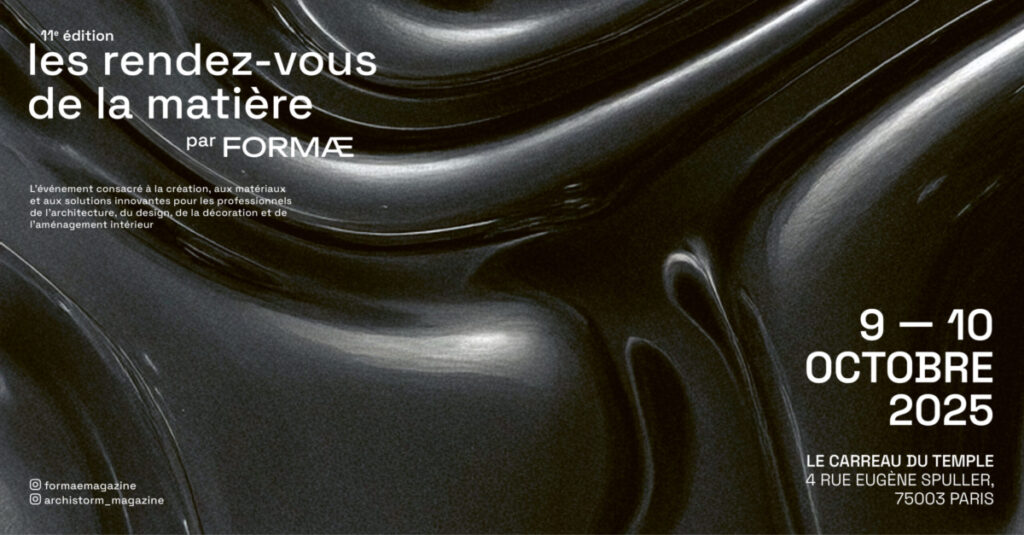

Authentic Material expose à la 11ème édition des rendez-vous de la matière par FORMAE.

Lire la suite

11/06/2025

June events: Meet us at BLOSSOM Paris & FUTURE FABRICS EXPO London

Lire la suite

03/12/2024

Authentic Material, manufacture de matériaux naturels, organise son premier vernissage : Pierre de Cuir, l’alchimie créative.

Lire la suite

14/11/2024

Arkema and Authentic Material partner to offer innovative and more sustainable materials for the luxury goods market and beyond

Lire la suite

16/10/2024

Authentic Material exhibits for the first time at FUTURE FABRICS EXPO in New York

Lire la suite

10/09/2024

Authentic Material exhibits for the first time at LINEAPPELLE MILAN

Lire la suite

04/09/2024

Une rentrée au Sustainable Leather Forum, Paris

Lire la suite

28/08/2024

Circularité du cuir : boucle ouverte et boucle fermée

Lire la suite